The Hierarchy of Control & WHS

When an employee is injured in the workplace, the next step is to review the events leading up to the incident—after any medical assistance, of course! The outcome of the review will often result in:

Tighter controls

Better training

More PPE

This is great, but wouldn’t it be better if the risk could be eliminated entirely?

Well, that’s where the Hierarchy of Control comes in. When considering the causes and outcomes of a workplace incident—or risk identified by a risk assessment—the best course of action is to work through a series of possible risk control measures.

Because what’s better than simply reducing the chance of risk? Eliminating it completely.

What is the Hierarchy of Control anyway?

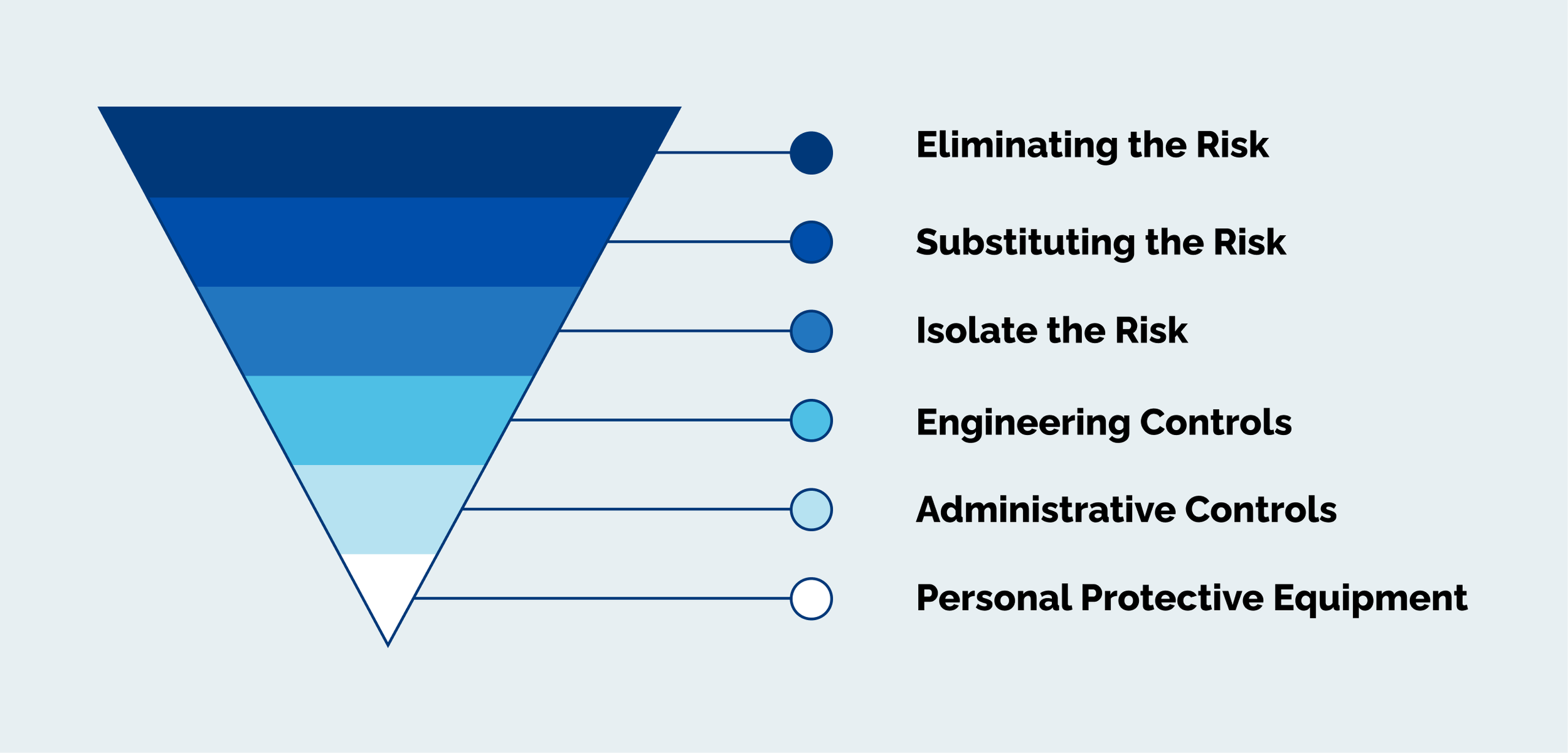

The Hierarchy of Control pyramid is a sequence of steps that should be considered when evaluating ways to remove or reduce a discovered risk.

Think of it like the food pyramid—each part is important, but preference should be given to the control measures that are bigger in the hierarchical structure than those that are smaller. Or, more simply, when you look at the following image, start from top to bottom!

Of course, the most effective risk control will often come from simultaneously implementing a number of levels from the hierarchy.

What are the risk control measures, and where does each one fit into the hierarchy?

Eliminating the Risk (Level One)

Our highest level is complete risk elimination, and it is always the preferred option when available as it means there is zero chance of the incident reoccurring. While removing the risk altogether may not be possible, it should always be the first control measure explored (in most cases).

An example of risk elimination could be providing extending poles operated from the ground to access a high window latch rather than climbing a ladder, which presents a risk of falling.

Substituting the Risk (Level Two)

The next level down in the hierarchy is risk substitution. Risk substitution is the process of removing risk by replacing it with another that is either less likely to occur or less severe in its potential damages. Substitution is less preferred as it still leaves a risk present, even in a reduced form.

An example of risk substitution could be replacing noisy equipment with a quieter option or replacing a highly toxic chemical with a less dangerous version. After the substitution is complete, it’s important to conduct a new risk assessment to identify any new risks created by the substitution process.

Isolate the Risk (Level Three)

The third level in the hierarchy is risk isolation. Risk isolation is performed by placing some form of barrier between the employee and the risk factor to provide protection. The key difference between this level and risk elimination (level one) is that the risk is still present, but a barrier shields the employee. If the barrier were to fail or require bypass, the risk would return to being uncontrolled. Risk isolation could be enacted by placing dangerous machinery in a separate room from the operating and installing remote control systems.

Engineering Controls (Level Four)

Engineering risk control is the process of designing and installing additional safety features to workplace equipment. Safety features could be installing more stringent ventilation systems in toxic environments or installing guardrails on a raised walkway.

Administrative Controls (Level Five)

Level five of the hierarchy is administrative controls. These are measures the management and chain-of-command can implement to reduce the likelihood of a risk occurring. Measures could include providing dedicated training targeted at the risk or arranging work schedules to limit exposure times in hazardous environments.

Personal Protective Equipment (Level Six)

The final level in the hierarchy of risk control is the use of PPE. This level will likely be utilised regardless of what other levels are also being used to control risk. However, it remains at the bottom of the hierarchy as it doesn’t remove or reduce the risk itself. Instead, this level is designed to assume an incident will occur and protect the employee from harm when/if it does. PPE includes items such as hard hats, noise-reducing ear protection, cut-resistant gloves, and more.

How does the hierarchy increase workplace safety?

The risk control measures are implemented in order of their effectiveness at controlling the risk and preventing accidents or injury. Risk elimination sits at the top of the hierarchy as there is no better way to prevent accidents or injuries than completely removing the risk.

Following down the hierarchy, isolating a risk completely, for example, by moving a loud and vibrating machine into a room to be controlled remotely, is better than just installing some soundproofing (engineering) or limiting employee exposure times (administrative).

PPE is a somewhat unique control on the hierarchy, as it is both the least effective (sitting at the bottom) and most commonly used. That is because PPE still leaves the risk uncontrolled — the employee is only personally protected from injury when the risk causes an incident.

PPE is unique, though, as it will usually be used in conjunction with whatever other risk control measures have been implemented. It acts as a final line of defence. It is also easy and cheap to implement compared to engineering completely new machinery or safeguards, making it perfect to use in addition to other controls. It also offers the additional benefit of protecting the worker from injury due to undiscovered risks.

Following the hierarchy means that when implementing risk control measures, you will always implement the most effective and safest option before implementing measures that may leave room for an incident to still occur.

It is good practice to self-enforce the hierarchy. In some jurisdictions, it is also a legal requirement to attempt to eliminate risks before attempting any other control measures anyway, so why not get ahead from the outset?

Always remember: safety first!

Want to learn more about risk elimination? Get in touch with Conserve today, and subscribe to our newsletter for regular updates and insights!